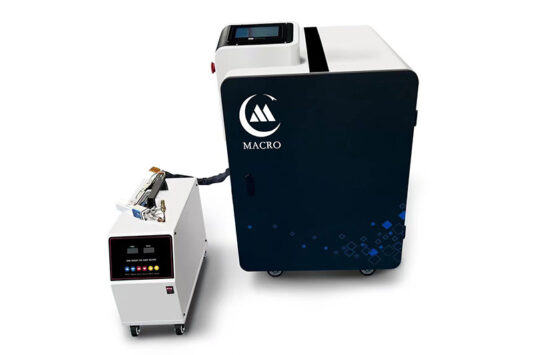

Flying Laser Marking Machine

5.0 (881)

Applicable types: fiber, co2, uv are all available

Applicable scenes: assembly line marking

Specially used for marking production lines

Automatic sorting time, codes, etc

Save a lot of time and manpower

Feature:

- The flying laser marking machine does not require manual operation on the production line, and its production capacity is several times that of the desktop laser marking machine.

- Flying dynamic marking means that there is no work surface, but a more flexible method, which can mark the surface of the product 360 degrees without restrictions, or it can be assembled on the assembly line and rotated in conjunction with the crawler to achieve product marking.

- It is fast and has a high degree of industrial automation, eliminating the need for additional manual positions. The configuration hardware of flying laser marking requires higher configuration than the hardware of stationary laser marking.

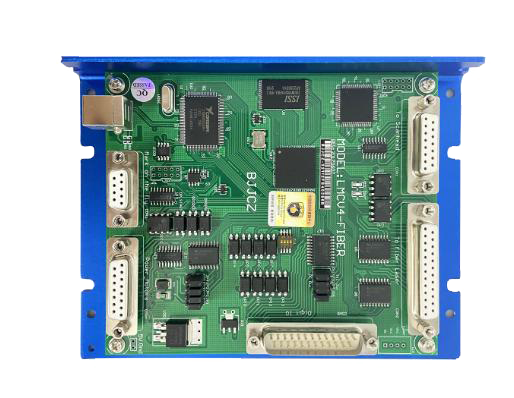

BJJCZ Control Board

Supports a wide range of engraving processes, and port-controlled features that make it easy to automate the machine.

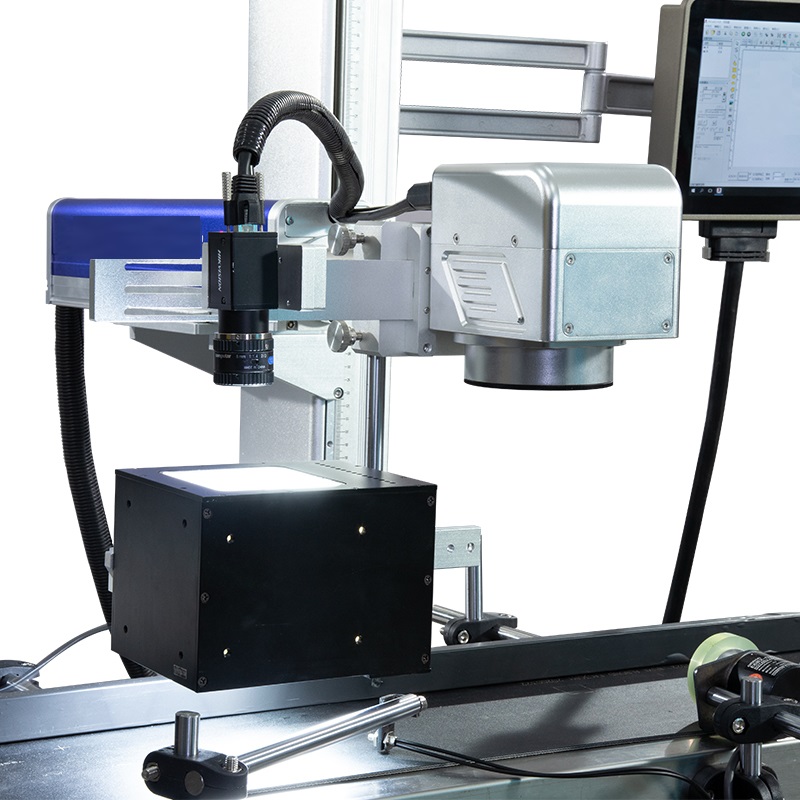

High Speed Digital Galvanometer

Adopting high-speed oscillating motor (optional US CTI motor and drive)

Encoder and Sensor

Quickly and accurately senses and recognises the speed and position of moving workpieces.

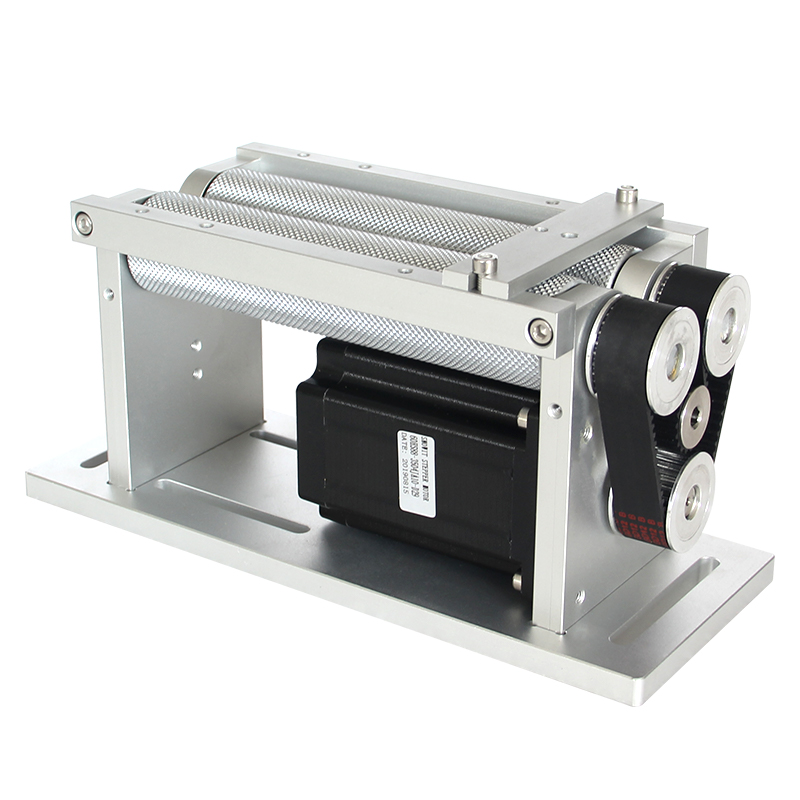

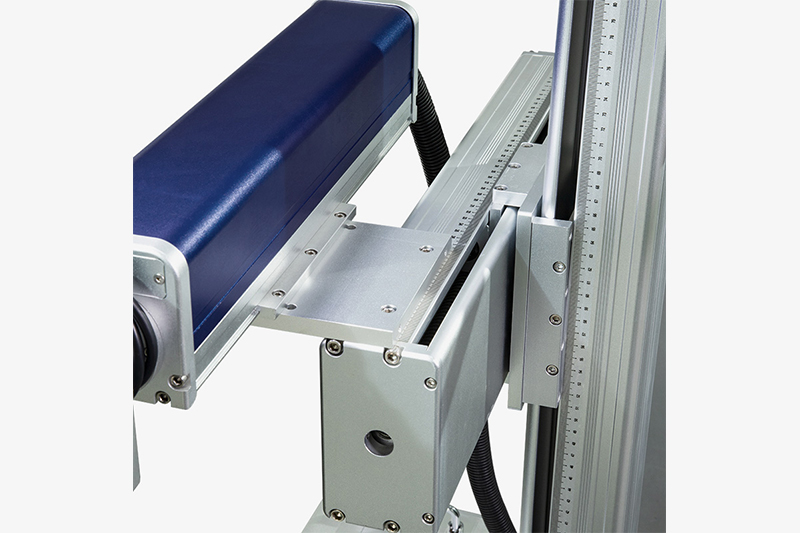

Flying Model Construction

1200 mm lifting range, front and rear displacement axes can be easily adjusted to suit industrial site requirements.

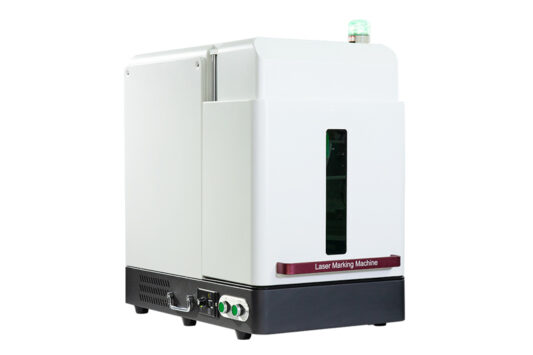

Touch Screen Marking System

- Flight models of touch-screen marking system, ultra-long text marking, two-dimensional code, dot-matrix encoder real-time tracking line speed jump marking, a variety of fonts to support a variety of industrial field of flight online marking

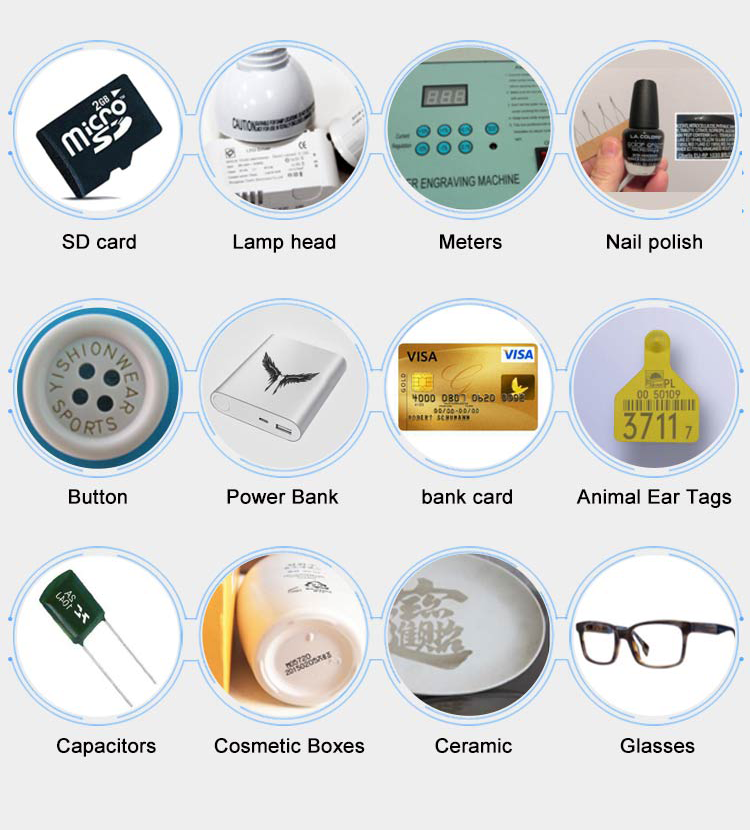

- Applicable materials

Apply to most non-metallic materials and part of the metal material assembly line marking, coding, etc.

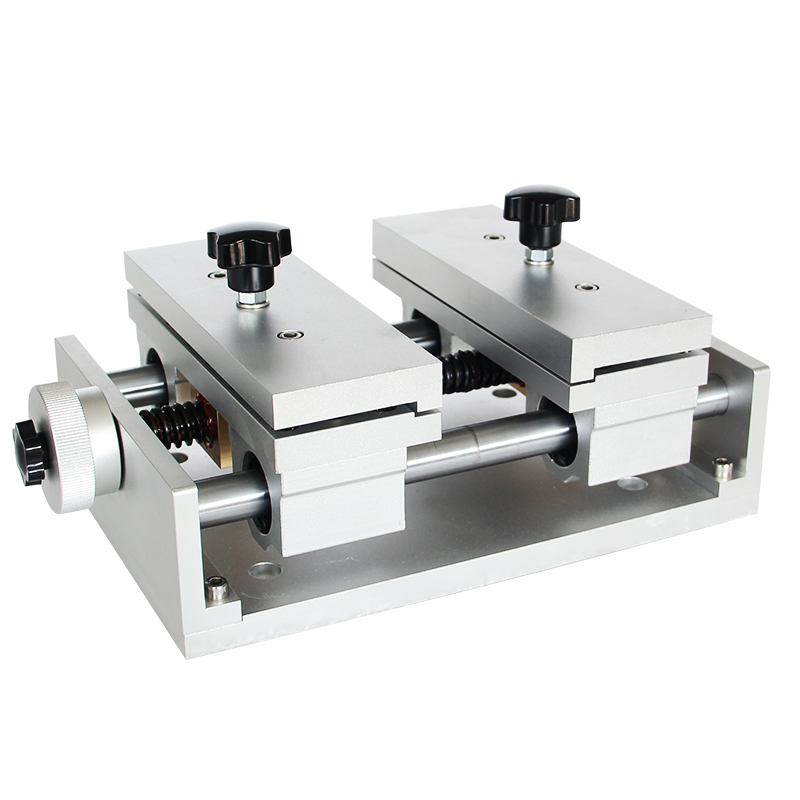

Optional Accessories

Technical Specifications

| Applicable materials | Metal and non-metals |

| Laser type | Fiber /Co2/UV |

| Marking head | Sino-Galvo or Qinlong flying marking galvanometer |

| Aluminum alloy pillar | 1200mm |

| Frequency of pulse | 20-80KHZ |

| Beam quality | M²:1.5 |

| Marking speed | 7000-12000mm/s |

| Marking depth | 0.01-1mm |

| Repetition Precision | 0.01mm |

| Minimum Line Width | 0.017mm |

| Minimum Character | 0.2mm |

| Cooling mode | Air cooling/Water cooling |

Laser Marking machine Sample